TRANSIT PDX SHIRT

DESIGN OVERVIEW

How could I create an insulated shirt that will keep the cyclist warm, dry, and not overheat during their bike commuting, and still look professional?

For this project I was inspired to make a mid-layer hybrid shirt that could be worn bike commuting and also stylish for the office or the bar. Using a wool shirt to pattern and inspiration from a technical jacket, this design is a cross between those two different designs.

I am proud that my work was selected for display during the College of Design 2023 accreditation audit by the National Association of Schools of Art and Design.

Course: Graduate Soft Goods Technology

When: December 2022 (3 weeks)

Role: Designer, Sewer

Process: Pattern replication, Material sourcing, Prototype, Testing, Presentation critique

Tools: Industrial sewing machine, Industrial serger, Illustrator, InDesign

PRODUCT GOAL

How could I create an insulated shirt that will keep the cyclist warm, dry, and not overheat during bike commuting, and still look professional?

DESIGN PROCESS

Determining the New Design

Starting with the Patagonia wool long sleeve that I already owned, I wanted a new design that was improved for my daily bike commute and durable for the rainy and cool Pacific Northwest weather. I also drew inspiration from the bike commute market and looked at the design features of the Rapha Insulation Overshirt.

New Design Features

Product Name: Transit PDX Shirt

Material: Change from wool to nylon ripstop

Thermal Insulation: Add front chest insulation

Storage: Add zippered chest pocket

Comfort: Add pocket hand-warmer

Nylon Ripstop

Zippered Chest Pocket

Insulation Layer

Inspiration Garment

Brand: Rapha

Product Name: Men’s Insulated Overshirt

Fabric: 50gsm outer nylon shell with DWR, Polartec Alpha

Price: $205

Reference Garment

Brand: Patagonia

Product Name: Long-Sleeved Wool Shirt

Fabric: 6.9 oz blend 60% recycled wool, 30% recycled polyester, 10% nylon

Price: $129

Prototype Process

Step 1: Pattern Making

Make pattern pieces from the Patagonia wool long sleeve.

Step 2: Cut Pattern Pieces

Cutting the pattern pieces.

Step 3: Sewing + Assembly

Sewing the chest pocket, drop pockets, and sleeves. Used top stitch and serge stitch.

Step 4: Fit Check

Confirm final fit and pattern piece accuracy

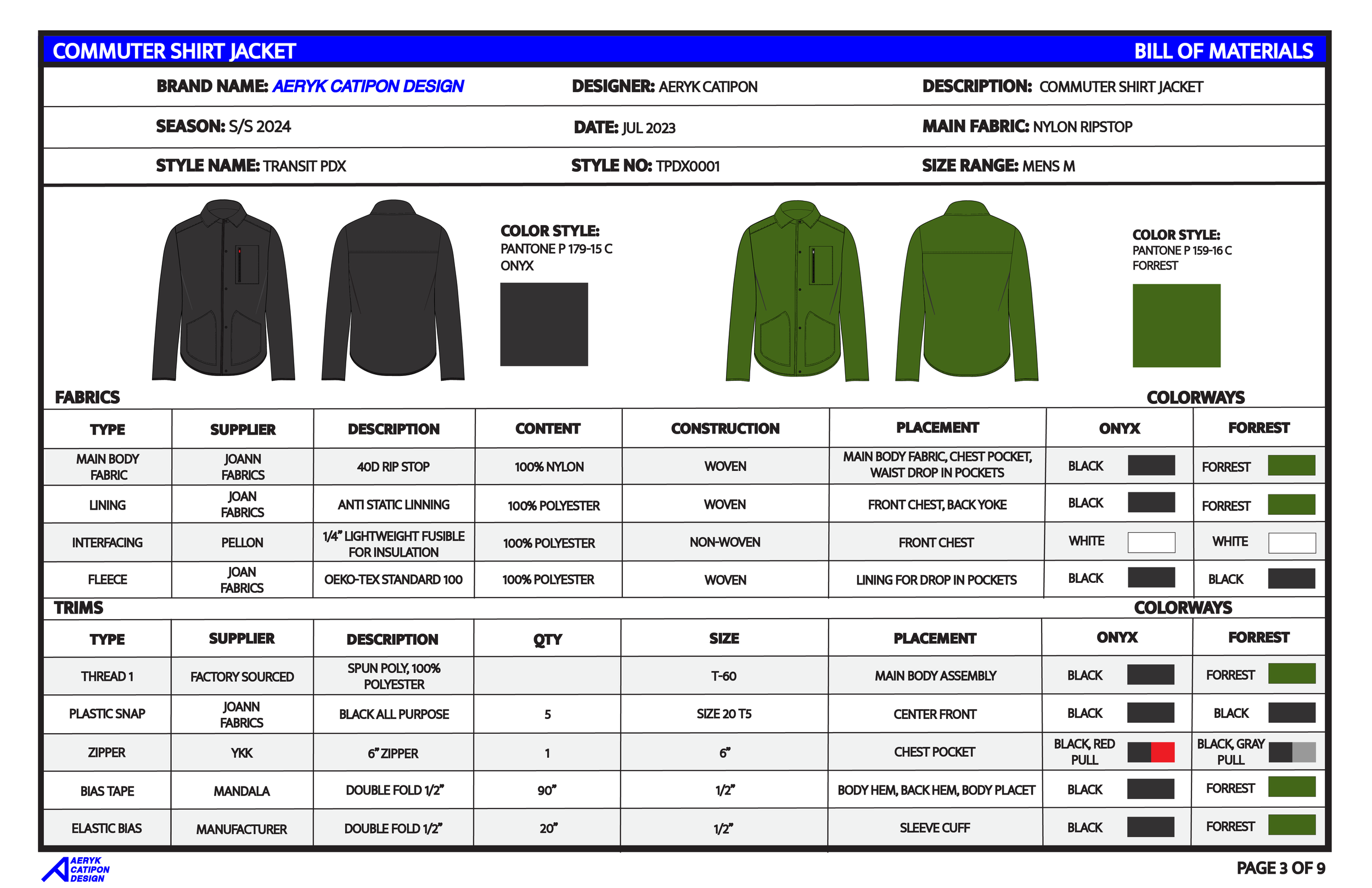

TECH PACK

FINAL PROTOTYPE

Transit PDX Shirt

Features & Benefits

Materials

Nylon ripstop, Polyester batting insulation, Fleece lined pockets, Plastic snaps and 6” zipper

Storage

3 pockets, 1 zippered chest, 2 drop-in waist pockets

Thermal Regulation

Hand warming pockets, Insulated front chest with lining, Non insulated back and sleeves for breathability, Wind and water resistant

TRANSIT PDX SHIRT

FUNCTIONAL FOR BIKE COMMUTING

PROFESSIONAL & STYLISH

DESIGN VALIDATION

Testing Conditions

40º F, 10 mph, 1 mile commute

Core was warm and did not overheat

Poured water on sleeve, did not soak through

Challenges

Slippery and shiny nylon material

First time sewing many construction features

Difficulty sewing consistent pocket sewing with grid fleece

Final Presentation Critique

At the final critique my professor did not recognize my garment. I wore it as part of my presentation and she could not tell that it was homemade. Part of the guest critique was that I should have added an additional seam allowance for the drop pockets as the interior seam was exposed. In addition I received feedback to use a pocket template for a more polished product, and to use wax paper to help with slippery fabric materials.

Overall I am pleased with how the final product turned out for my first designed garment. If I were to make this again I would make pocket templates and have a more finished hem for the drop pockets. I am proud that my work was selected for display during the College of Design, 2023 accreditation audit by the National Association of Schools of Art and Design.